Introduction

When it comes to building shelves, one of the most important considerations is the strength of the material used. Plywood is a common choice for shelf construction, but many people wonder if it is strong enough to support the weight of books, dishes, or other heavy items. While plywood may not be the strongest material available, it can certainly be strong enough for a shelf when used properly. In this article, we will explore the factors that contribute to plywood’s strength and discuss how to build shelves that are sturdy and reliable.

Plywood is a versatile material that can be used for a variety of projects, including shelving. While it is not as strong as some other materials, such as particle board or hardwood, it is sturdy enough for many applications. keep in mind, however, that the thickness of the plywood will affect its strength. Thicker plywood is better suited for shelving than thinner plywood.

What is plywood?

Plywood is a manufactured wood panel made from thin sheets of wood veneer. It is one of the most versatile wood products available and can be used for a variety of applications, including countertops, shelving, and more.

Plywood is made from multiple layers of wood veneer glued together. The grain of each layer is rotated 90 degrees from the adjacent layer, which gives plywood its strength. Plywood is available in a variety of thicknesses and sizes, and it can be either finished or unfinished.

Is MDF Or Plywood Better For Shelves?

When it comes to choosing the right material for your shelves, you may be wondering whether MDF or plywood is the better choice. Both materials have their advantages and disadvantages, and it ultimately comes down to your specific needs and preferences. In this section, we’ll take a closer look at MDF and plywood to help you make an informed decision. MDF, or medium-density fiberboard, is a type of engineered wood made by breaking down hardwood or softwood residuals into wood fibers. These fibers are then combined with wax and a resin binder to form a dense, uniform board. MDF is a popular choice for shelves because it is smooth, flat, and has no knots or voids. It also has a uniform density, which means it is consistent in strength and thickness throughout the board.

One of the biggest advantages of MDF is its affordability. It is generally less expensive than plywood, making it a popular choice for those on a budget. MDF is also easy to work with, as it can be cut, drilled, and routed with ease. Additionally, MDF is a good choice if you plan on painting your shelves, as it has a smooth surface that takes paint well.

However, MDF does have some disadvantages. It is not as strong as plywood, and can sag or warp over time if not properly supported. It is also more susceptible to moisture damage than plywood, as it is made from wood fibers that can absorb water. If you plan on using your shelves in a damp environment, or if you need them to support heavy objects, MDF may not be the best choice.

Plywood, on the other hand, is made by layering thin sheets of wood veneer together with adhesive. The layers are oriented at right angles to one another, which gives plywood its strength and stability. Plywood is a popular choice for shelves because it is strong, durable, and resistant to warping and cracking. It is also less susceptible to moisture damage than MDF, as the layers of veneer are less likely to absorb water.

One of the advantages of plywood is its strength. Plywood is able to support heavy objects without sagging or warping, which makes it a good choice for shelves that will be holding a lot of weight. Plywood is also more durable than MDF and is less likely to chip or crack over time.

However, plywood does have some disadvantages. It is more expensive than MDF, which may be a factor if you are on a tight budget. Plywood can also be more difficult to work with than MDF, as it can be prone to splintering and tearing when cut or drilled. Additionally, plywood does not have the smooth surface of MDF, which may make it more difficult to paint or finish.

The different types of plywood

Plywood is a versatile and durable building material that is commonly used in construction, furniture making, and home improvement projects. It is made by gluing together thin layers of wood veneers, which are cross-laminated to increase strength and stability. Plywood is available in a variety of types, each with its own unique characteristics and uses. Here are some of the different types of plywood and their properties:

1. Softwood Plywood

Softwood plywood is made from coniferous trees, such as pine, spruce, or fir. It is typically used for construction purposes, such as sheathing or subflooring. Softwood plywood is relatively inexpensive and easy to work with, making it a popular choice for DIY projects.

2. Hardwood Plywood

Hardwood plywood is made from deciduous trees, such as oak, birch, or maple. It is known for its strength and durability, making it a popular choice for furniture and cabinetry. Hardwood plywood is more expensive than softwood plywood, but it is also more resistant to warping and shrinking.

3. Marine Plywood

Marine plywood is a type of hardwood plywood that is designed for use in wet or humid conditions. It is made with waterproof glue and is highly resistant to rot, making it ideal for boat building and other marine applications. Marine plywood is more expensive than other types of plywood, but its durability makes it a worthwhile investment.

4. Structural Plywood

Structural plywood is designed for use in construction applications where strength and stability are essential. It is made with high-quality veneers and is typically used for roofing, flooring, and wall sheathing. Structural plywood is graded according to its strength and stiffness, with higher grades indicating greater strength.

5. Fire-Rated Plywood

Fire-rated plywood is designed to resist flames and is used in applications where fire safety is a concern. It is made with special fire-retardant chemicals that slow the spread of flames and reduce smoke production. Fire-rated plywood is typically used in commercial buildings, such as schools and hospitals.

6. Decorative Plywood

Decorative plywood is designed for use in furniture and cabinetry where appearance is important. It is made with high-quality veneers that are carefully selected for their color and grain pattern. Decorative plywood is available in a variety of finishes, including natural wood veneers, painted finishes, and laminates.

7. Overlaid Plywood

Overlaid plywood is designed for use in applications where durability and resistance to abrasion are important. It is made with a layer of high-density fiberboard or particleboard that is overlaid with a thin layer of hardwood veneer. Overlaid plywood is commonly used in commercial applications, such as retail fixtures and displays.

What Is The Best Type Of Plywood For Storage Shelves?

When it comes to building storage shelves, one of the most important decisions you’ll make is the type of plywood you use. Plywood is an engineered wood product made from thin layers of wood veneer. It’s a strong, durable, and versatile material that can be used in a wide range of applications, but not all types of plywood are created equal. In this post, we’ll take a look at the best types of plywood for storage shelves and what makes them a good choice.1. MDF Plywood

MDF plywood is a popular choice for storage shelves due to its durability and strength. MDF stands for medium-density fiberboard, which is made from wood fibers that have been compressed and bonded together with resin. The result is a strong and stable material that is resistant to warping and splitting, making it ideal for shelving.

One of the benefits of MDF plywood is that it has a smooth, uniform surface that is easy to paint or laminate. This makes it a great choice if you want to customize your shelves with a specific color or finish.

2. Baltic Birch Plywood

Baltic birch plywood is another top choice for storage shelves. This type of plywood is made from multiple layers of birch veneer that are cross-banded and glued together. The result is a strong and stable material that is resistant to warping and twisting.

Baltic birch plywood is also known for its attractive appearance. It has a pale, uniform color and a smooth surface that is perfect for staining or painting. This makes it a great choice if you want your shelves to look as good as they perform.

3. CDX Plywood

CDX plywood is a more affordable option for storage shelves. This type of plywood is made from layers of softwood veneer that are bonded together with a waterproof adhesive. The exterior layers are treated with a sealer or coating to make them water-resistant.

While CDX plywood is not as strong as MDF or Baltic birch plywood, it is still a good choice for lighter loads. It’s also a great option if you’re on a tight budget and want to save money without sacrificing quality.

4. Marine Plywood

Marine plywood is a premium grade of plywood that is designed for use in wet environments. It’s made from high-quality hardwood veneers that are bonded together with waterproof glue. The exterior layers are treated with a special coating that makes them highly resistant to water and moisture.

While marine plywood is more expensive than other types of plywood, it’s a great choice if you’re building shelves in a damp or humid area, such as a basement or garage. It’s also a good choice if you want shelves that will last for many years without warping or deteriorating.

How thick should plywood be for shelves?

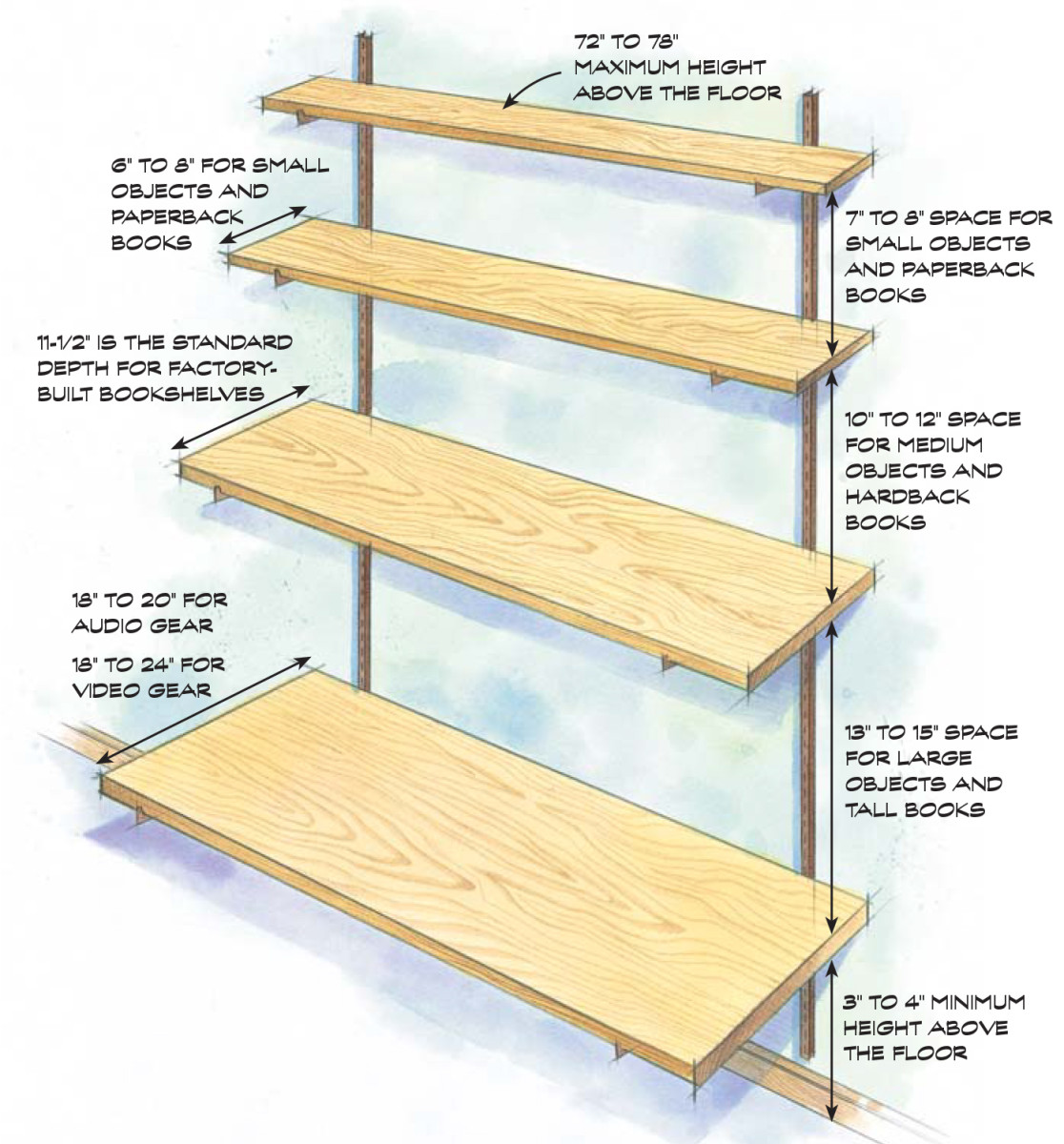

When considering plywood thickness for shelves, several factors should be taken into account, such as the weight of the items to be stored and the spacing of the shelves. Additionally, the type of plywood used and the method of installation can affect the necessary thickness. Therefore, it is important to carefully evaluate these factors before determining the ideal thickness for plywood shelves. Consequently, it is important to carefully evaluate the necessary considerations; however, ultimately, the ideal thickness for plywood shelves will depend on the specific circumstances of the project.

Is plywood for shelves a good idea?

Yes, plywood can be a good material for shelves. However, it depends on the thickness and quality of the plywood. Additionally, reinforcing the shelves with brackets or supports can increase their durability. Therefore, while plywood is a cost-effective option for shelves, it’s important to consider the necessary precautions to ensure they are sturdy enough for their intended use.

How strong is a plywood shelf?

Plywood shelves can be quite strong, but it depends on the type of plywood used and the construction method. Additionally, the weight and distribution of objects placed on the shelf can also affect their strength. Therefore, it is important to carefully consider these factors before building or relying on a plywood shelf. Consequently, in conclusion, plywood shelves can be strong, but it is crucial to use the appropriate materials and construction techniques, and to consider the weight and distribution of objects placed on the shelf.

Making Plywood Storage Shelves

Plywood is a versatile and affordable material that can be used in a variety of DIY projects. One of the most popular uses for plywood is in building storage shelves. Plywood storage shelves are easy to build, customizable, and can add valuable storage space to any room in your home. In this blog post, we’ll explore the steps involved in making plywood storage shelves and provide some tips for making the process as smooth as possible.

Step 1: Gather Your Materials

Before you start building your plywood storage shelves, you’ll need to gather all of the necessary materials. Here’s what you’ll need:

– Plywood sheets: The number of sheets you need will depend on the size and number of shelves you plan to build. Make sure to choose high-quality plywood that is free of knots and other defects.

– Saw: You’ll need a saw to cut the plywood sheets to the desired size.

– Drill: A drill will be used to make holes for screws and other hardware.

– Screws: You’ll need screws to attach the plywood sheets together and to secure the shelves to the wall.

– Level: A level will be used to ensure that your shelves are straight and level.

– Measuring tape: You’ll need a measuring tape to measure the size of your shelves and ensure that everything is spaced properly.

Step 2: Cut Your Plywood Sheets

Once you have all of your materials, it’s time to cut your plywood sheets to the desired size. Use a saw to cut the sheets to the proper length and width. Make sure to measure carefully to ensure that all of your shelves are the same size.

Step 3: Drill Holes for Screws

Next, you’ll need to drill holes for your screws. This will help ensure that your shelves are sturdy and secure. Drill pilot holes in the corners of each plywood sheet and then drill additional holes along the edges, spacing them evenly apart.

Step 4: Assemble Your Shelves

Now it’s time to assemble your shelves. Start by attaching two plywood sheets together using screws. Then, attach a third sheet to the top of the first two sheets using screws. Continue this process until you have all of the shelves assembled.

Step 5: Attach Your Shelves to the Wall

Once your shelves are assembled, it’s time to attach them to the wall. Use a level to ensure that your shelves are straight and then mark where the screws will go. Drill pilot holes into the wall and then attach the shelves using screws.

Step 6: Add Finishing Touches

Finally, it’s time to add some finishing touches to your shelves. Sand the edges of the plywood sheets to smooth them out and remove any rough spots. You can also paint or stain your shelves to match your decor.

Tips for Making Plywood Storage Shelves

– Measure carefully to ensure that all of your shelves are the same size.

– Use high-quality plywood to ensure that your shelves are sturdy and durable.

– Drill pilot holes to prevent the wood from splitting when you drive in screws.

– Use a level to ensure that your shelves are straight and level.

– Sand the edges of your plywood sheets to remove any rough spots and ensure a smooth finish.

In conclusion, making plywood storage shelves is a great DIY project that can add valuable storage space to your home. With the right materials and tools, anyone can build their own plywood storage shelves. Follow the steps outlined in this blog post and use our tips to make the process as smooth and easy as possible. Happy building!

The benefits of plywood

Many people don’t realize that plywood is actually stronger than lumber of the same thickness. This is because plywood is made up of multiple layers of wood veneer, with the grain of each layer running in opposite directions. This gives plywood added strength and stability.

Plywood is also less likely to warp or cupping than lumber, making it an ideal choice for shelves.

The disadvantages of plywood

Plywood is cheap, but it has several disadvantages that make it a less-than-ideal choice for certain projects.

First, plywood is not as strong as other types of wood. It is more likely to warp or sag over time, especially if it is not properly supported.

Second, plywood is not very durable. It is susceptible to water damage and can easily be scratched or dented.

Third, plywood does not hold screws or nails as well as other wood. This means that it is not a good choice for projects that require a lot of hardware, such as shelves or cabinets.

Fourth, plywood can be difficult to work with because of its tendency to crack and splinter.

Overall, plywood has some significant disadvantages that should be considered before using it for a project.

Which One Is The Best Material To Use For Shelving?

For many DIYers and homeowners, plywood is a go-to material for shelving projects. Lightweight, inexpensive, and easy to work with, plywood is an ideal choice for building shelves that will be used to store lighter items.

However, some people have doubts about whether plywood is strong enough to be used for shelving. After all, it is a wood product, and wood can be prone to warping and sagging over time, especially if it is not properly supported.

So, what is the verdict? Is plywood strong enough for a shelf?

Yes, plywood is strong enough for a shelf. Though it is not as strong as some other materials like particle board or MDF, it is still plenty strong enough to support the weight of most items that would typically be stored on a shelf. And, if you take steps to reinforce your shelves (by adding braces or supports), you can further increase their strength and capacity.

If you cannot find an answer on our website to your question, feel free to message or call us!